Crushing, Grinding, Emulsification, Mixing and Pumping

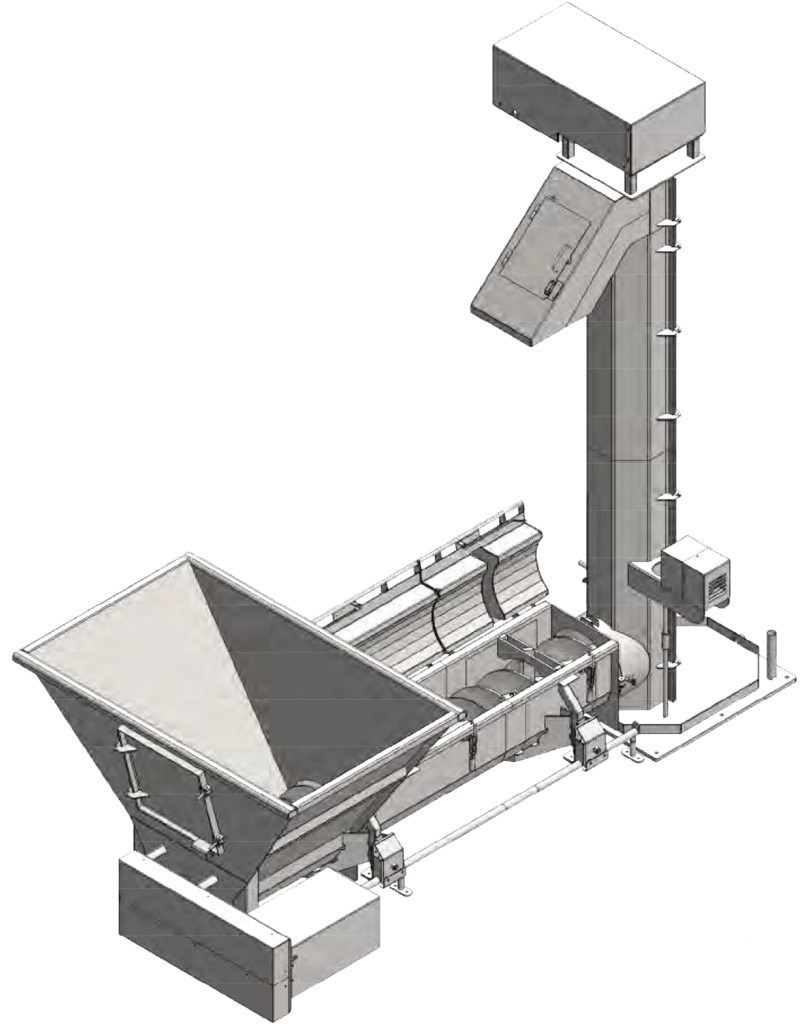

Whole Pallet Crushers/Breakers

The scansteel foodtech Whole Pallet Crusher, WPC, range is probably among the most comprehensive available. The entire cabinet and frame structure is manufactured in stainless steel AISI 304.

The WPC is available with single or double rotary claw shafts. The infeed width is available in either 1500 mm or 2000 mm. Gear box(es) are equipped with individual oil cooler. The Heavy Duty design is performed with main bearing positioned on each side of the end of the claws shaft thus eliminating all axial forces between the claws and gear box.

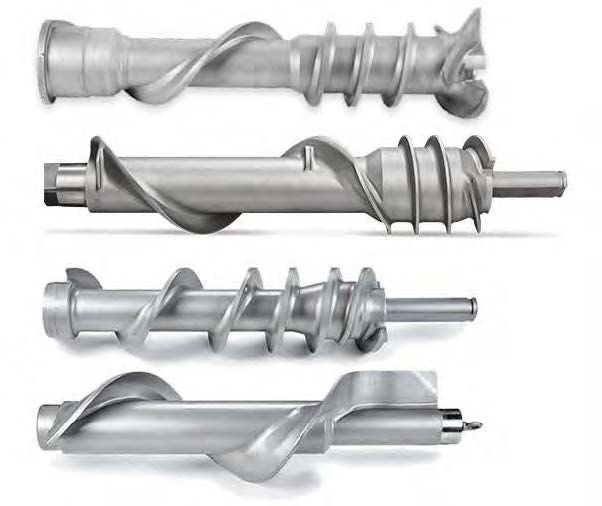

Grinders

Over the years, Scansteel has conquered the position as THE supplier with the world’s widest and most comprehensive grinder program. Our grinders are normally used for (but not limited to) the following applications:

• Fresh meat raw material

• Frozen blocks of meat raw material

• Pre-crushed/broken whole pallets of frozen blocks

• Bones – beef, pork, poultry, fish, etc

• Fat – all types and temperatures

• Fish – all types

• Fish offal

• By-products

These truly unique and universal grinders provide first-class grinding results, fully comparable with and even surpassing those of conventionally specialized grinders for fresh, tempered, or deep-frozen blocks without changing anything but the incoming raw material to be ground, coarsely or finely, as required.

SuperGrind SG 400/260

The Toughest of Meat Raw Material Grinders

Scansteel SuperGrind 400/260 (SG 400/260) is within its size/capacity probably the toughest and most Heavy Duty “Work Horse” among meat raw material grinders. Designed specifically for global pet food and rendering industries for grinding of entire beef bones (all types, including femur bones), entire pork bones (all types, including femur), all types of poultry and fish bones, pre-broken bones and soft meat raw material.

Mixers

Scansteel supplies a full range of Mixers and Mixer/Grinders for the global food processing industry as well as the global pet food industry, from 200 L to 12,000 L. Features include the below; many added optional features available.

• Constructed in stainless steel AISI 304

• Safety equipment for CE conformity

• Low energy consumption

• Ideal for frozen meat and fresh/frozen mixtures. A flexible and high-performance mixing is given with both a high peripheral wing speed and a gentle handling of the mentioned raw materials

• Minimum product residues and cross-mixing of batches, also including fully separated and sealed hygienic one preventing any possible cross contamination

• Various lid configurations: rear or side hinged. Optional as pneumatically operated

• Computerized design of mixing wings and mixer geometry combined with the

programmable mixing action secure optimum processing results for you

• Low noise level

• Mixer controls available in range from ordinary push button operated versions to advanced PLC controlled systems. All PLC systems are supplied with reliable and easy accessible finger-touch operator panel with digital read-out of all mixer functions. Make Allen Bradley

Pumps

The Scansteel SuperPump series comprises 3 different pump sizes. Correct choice of pump depends on several factors such as, but not limited to, pump capacity, material to be pumped, temperature, viscosity, and particle size – from pre-ground meat raw material to half a pork carcass. One significant feature is the double discharge outlet which dramatically minimizes (eliminates) fluctuations in pump capacity. Motor for pumps is designed according to pump application.

Visit https://www.scansteelfoodtech.com/ for more information.

YOUR PARTNER IN UNIQUE PROCESSING SOLUTIONS

Speak to a Scan American Sales Engineer Today