Distillation, Extraction and Evaporation

Aroma Recovery

Better Flavors, Better Aromas

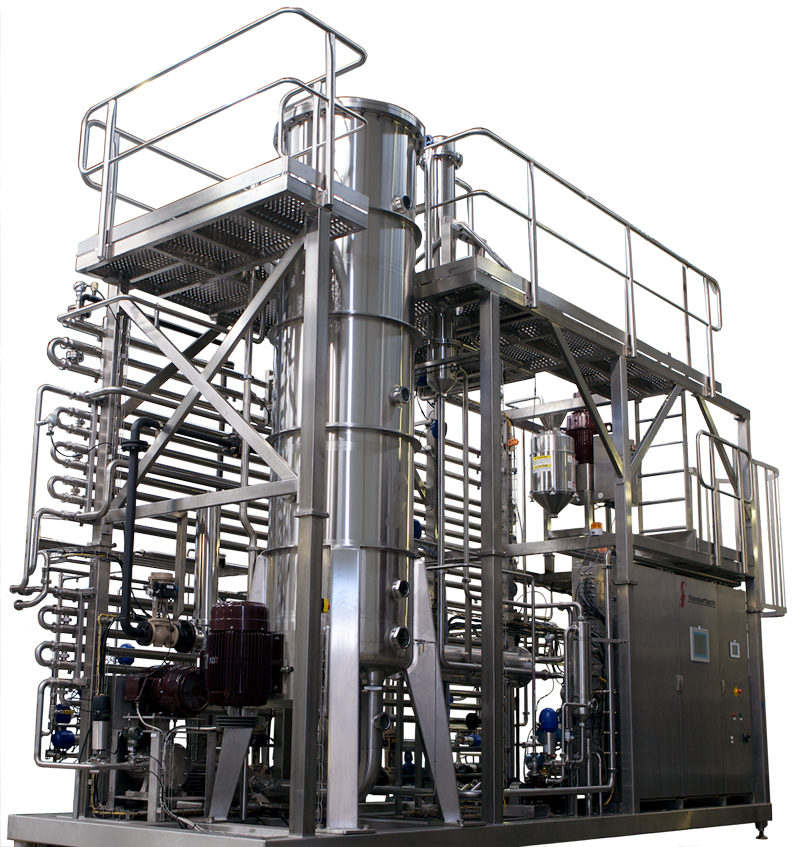

Our flagship product – the Spinning Cone Column (SCC) – is designed to extract and recover volatile compounds using steam, under vacuum conditions. This is a far more gentle process compared to standard extraction techniques, enabling our equipment to better capture aromas and flavors – naturally.

Used across multiple industries, applications for the SCC include:

- Aroma recovery during instant coffee production

- Simultaneous flavor and soluble solids extraction from coffee and tea slurries for the production of ready-to-drink (RTD) beverages

- Dealcoholization and alcohol management in wine, beer and other alcoholic beverages

- Deodorization of cream and flavor management of dairy products

- Aroma recovery and preservation during production of fruit and vegetable purees and juices

- De-oiling of NFC (Not From Concentrate) citrus juices

- Essential oil extraction from botanicals, herbs and spices

- Extraction of pure flavors from fresh fruits

The SCC has been proven to deliver significant returns on investment through the recovery of superior flavors, aromas and extracts by maintaining the natural characteristics of the raw material. Equipped with state of the art control and automation, and built using 316 grade stainless steel for all product contact surfaces, the SCC operates as a continuous processing system delivering superb operational efficiency and maximizing factory uptime

Thin Film Evaporator

Retain your product’s functional properties – Naturally

Clever in design, the Centritherm® evaporator is much more compact than competing evaporators and can be installed quickly with minimal infrastructure requirements. A simple operator interface makes it easy to use and a built-in cleaning system means changeover from one product to the next is quick and easy.

Furthermore, its centrifugal design means it can reach higher concentrations than other evaporators and it is often used as a finisher in the evaporation process to reduce process and energy requirements downstream.

Applications of the Centritherm® evaporator include:

- High quality tea and coffee concentrates

- High quality fruit and vegetable concentrates

- Solvent removal from botanicals and oleoresins

- Solvent removal in the pharmaceutical industry

- Concentration of vitamins, enzymes and active ingredients

Integrated Extraction System

Leaders in tasted technology

Flavourtech’s Integrated Extraction System (IES) is a continuous, automated processing line that allows customers to produce premium aromas, extracts and concentrates for the Ready-to-Drink (RTD) coffee and tea market, the instant coffee industry and for the fragrance and flavor industry. Built as a modular system, the IES can be inserted into existing process lines as required to make gradual improvements, or installed in its entirety to form a continuous process line, allowing aroma recovery, extraction and concentration in one simple-to-operate system.

As a semi or fully automated system, an IES process line can be operated with minimal staff. The easy-to-clean design allows different products to be processed with minimal downtime between runs. Quality is assured, as the modules are programmed for consistent results from run to run.

IES modules available include:

- Slurry Preparation module

- Flavour Extraction module

- High temperature extraction module (for instant coffee production)

- Solids separation module

- Clarification module

- Filtration module

- Wash module

- Concentration module

The IES is Flavourtech’s solution for those looking to deliver market leading RTD tea and coffee products to discerning consumers around the world.

Visit https://flavourtech.com/ for more information.