How X-Ray Inspections Can Prevent Contamination in the Food and Drink Industry

Sapphire x-ray inspections are changing the way food is processed. As technology continues to improve and advance, so do the benefits. It not only allows food to be safer, but it saves manufacturers a lot of money.

Food can become contaminated in many different ways, which means inspections need to be ongoing. But with Sapphire x-ray inspections will ensure your products are safe.

How Sapphire X-Ray Inspections Can Prevent Contamination in the Food and Drink Industry

There are any number of foreign objects that can get into food and beverages during processing. Metal, plastic, glass, rubber, bones, and stones, to name a few.

These can contaminate food during processing in several different ways without being detected. Sapphire x-rays will detect them. X-rays can save money and your reputation.

Product Recall

The last thing your company needs is a nationwide recall. This is not only extremely expensive but the damage to your brand can be devastating. Not only do you pay to recall the product, but you also stand to lose millions when people stop buying your product.

If there are incidents beyond the contamination, like lawsuits or people trying to press charges, it can be almost impossible to come out of it on top. Other consumers will side with the injured part.

Quality Assurance

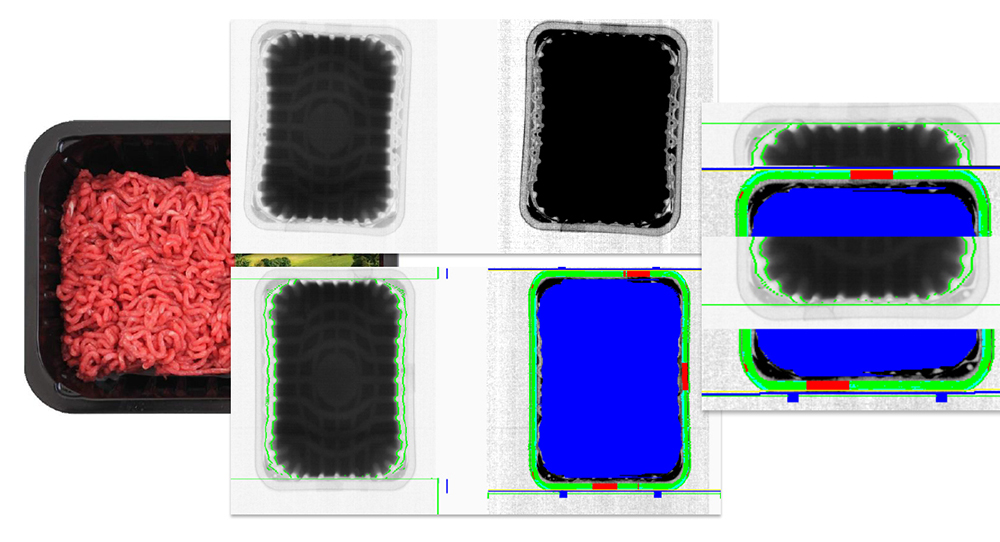

Sapphire x-ray inspections can also detect the quality of the product. One scan can find problems like broken pieces or damaged packaging, missing items, fill levels, and checking that the product is sealed properly.

This saves a lot of time and money if you are having to do this manually. Too many smaller concerns can and do get missed. It’s impossible to know what is going on inside the packages once they are sealed.

Protecting the Consumer

Consumers finding contaminants or foreign objects in their food or drinks is bad enough, but it is worse if someone gets sick or injured. People can get cut or injured from things in the food, like glass or metal.

People may also get sick or have an allergic reaction to something that should not be in the product. This can quite often mean a lawsuit or having to pay out damages. It will also hurt your reputation.

Meet Regulatory Standards

Why take chances? If there is a problem or something questionable regarding one of your products, you can have the assurance you took all the necessary steps to ensure your products were inspected thoroughly before they left the plant.

Frivolous lawsuits may not go anywhere, but they are still a costly nuisance. With Sapphire x-ray inspections, you can be sure your product was completely up to code before it went to market.

Customer Retention

Your customers need to be able to trust that the product they are buying and consuming is safe. Competition can be brutal in the food and beverage industry.

Loyal customers mean returning customers. You want them to keep coming back to the products they love. Let them know you use all the advanced technology to ensure the products they are consuming are safe.

Sapphire X-Ray Inspections

If you are looking at stepping up your production lines, the addition of any of our Saphire x-ray inspection machines will be an asset to your company. Save money and time and do a complete inspection every time.

Sapphire Inspection Systems have developed sophisticated, multi-use machines for hundreds of categories worldwide. Select your industry type below to discover how we help create safer products for your sector.