Mixing and Homogenizing Systems

Vacuum Mixing & Homogenizing

Symex, the premium solution for pharmaceutical and cosmetics production, develops and produces vacuum mixing and homogenizing plants for the manufacturing of liquid, pourable and semisolid emulsions and suspensions:

- Lab scale from 4 – 30-liter batch capacity

- Pilot plant station scale from 30 – 200-liter batch capacity

- Production plant scale up to 20,000-liter batch capacity

- All plants can be included with one or more phase vessels.

All plant concepts can be augmented by special operation solutions: Emulsifying equipment, explosion protection according to ATEX/NEC/CEC, fully automatic cleaning and sterilization capability, fully automatic batch systems, and high volume raw material feeding systems etc.

Our advantages include:

- 100% repeatable product quality (viscosity, particle size distribution and stability)

- Significant reduction in processing times

- Improvement in product stability

- Significant reduction in cleaning times and media consumption

- Optimum temperature guidance

- Automated, safe and repeatable raw material handling

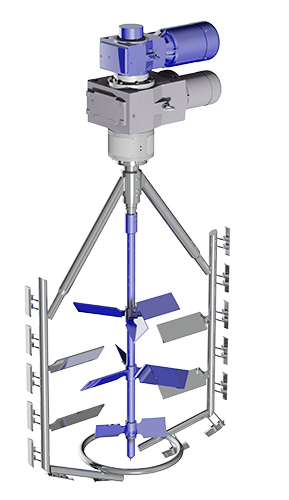

Coaxial Agitator

Complete control of the mixing profile in the vessel at all speeds and viscosities

• Mixing up to 1,500,000 cP product viscosity

• Counter rotation with independent speed settings for both agitators

• Excellent temperature distribution

• Quick and homogeneous mixing

• Optimum cleaning (fast and residue-free)

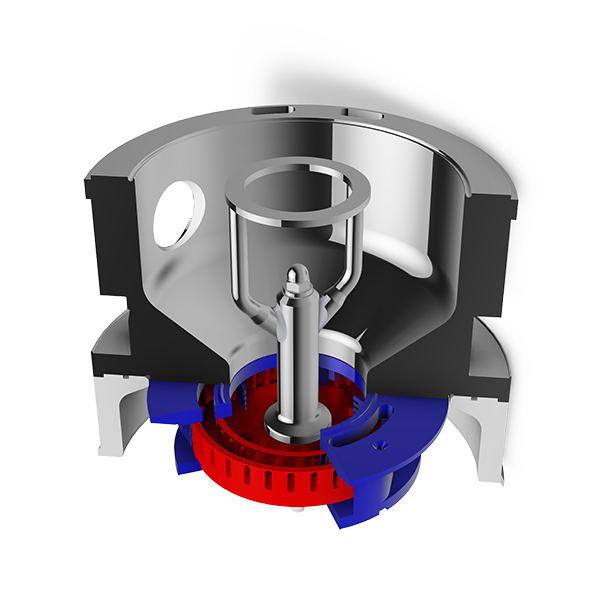

Co-Twister Homogenizer

Independent control of flow and shear

• Rotor-Rotor Principle

• 2 separate drive motors

• 0-70 m/s differential speed in the shear gap (shear speed)

• High pumping output for homogenization and CIP

• Quick homogenization of highly viscous and shear-sensitive products

• Direct influence on droplet and particle size

• Product discharge without shear (replaces discharge pumps)

• Pigment grinding (replaces mills of all kinds)

• Highest energy density (replaces high-pressure homogenizers)

Temperature Control System

Secondary circuit system for controlled and precise temperature management

• Control accuracy of +/-0.5 °C of product temperature

• Double heat exchanger systems (heating and cooling)

• No direct steam or cooling water supply in the double jacket

• 4 different control modes (Quick/Ramp/Delta-T/Inlet)

• Inlet temperature limitation

Visit https://symex.de for more information.

YOUR PARTNER IN UNIQUE PROCESSING SOLUTIONS

Speak to a Scan American Sales Engineer Today